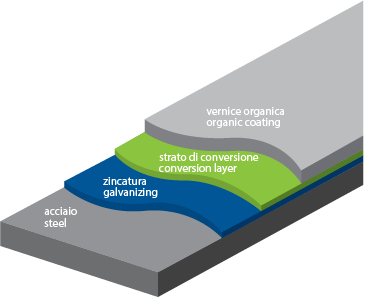

Protection from the heat, thanks to the use of sun control glass panes, with a metallic/reflecting surface layer which prevents overheating the environments allowing the introduction of economies on the functioning of the air-conditioning plant and thus promoting energy-saving and home comfort. Their efficiency is quantified by the g value, or rather the solar factor; the lower the factor, the greater the performance.

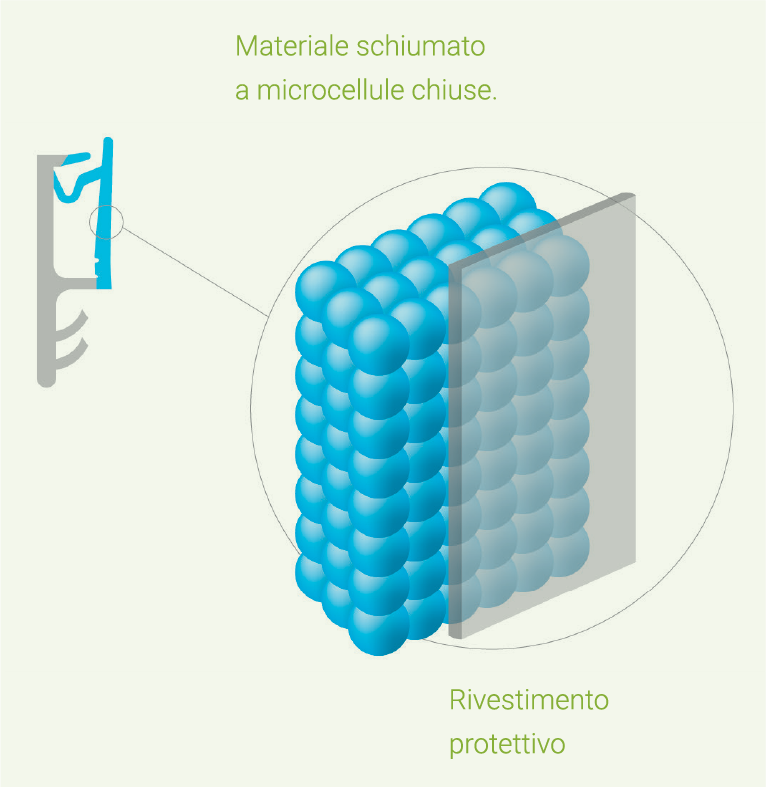

Protection from the cold, thanks to the use of glass low emission discharge with a superficial covering layer of colourless metal, which prevents the dispersion of heat towards the outside, making the temperature of the ambiences more homogeneous and contributing towards reducing heat consumption.

Heat-cold protection thanks to the use of glass with a selective deposit which improves home comfort by interacting with the summer and winter heat flows, thereby ensuring an optimal performance throughout the seasons.

These features allow the use of our windows in any climatic zone and also for buildings parameterized to the values of the Passive House.